Stainless Steel Press Fittings M, Secure and Fast Connections

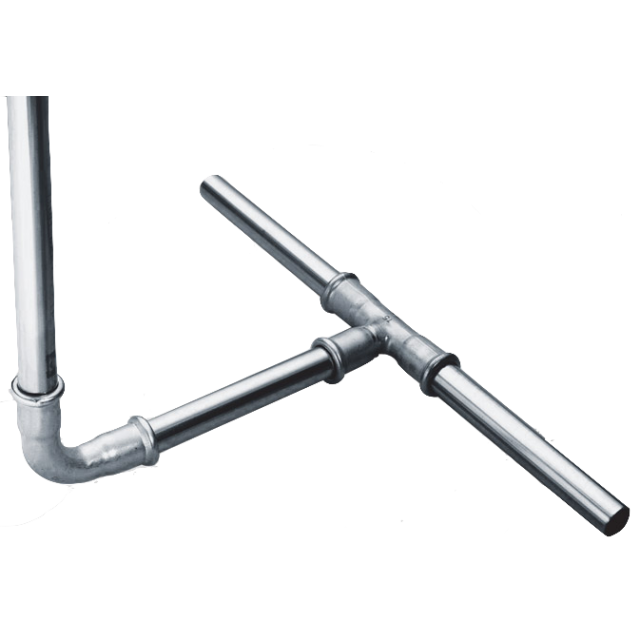

Swiss Fittings carries a wide portfolio of stainless steel M Press fittings, including sockets, elbows, unions, tees, and adapters. All stainless steel press fittings offered have the DVGW, ÖVGW, and SVGW certificate, and can be connected with the also offered stainless steel pipe. These press fittings are system-independent, therefore can be installed and pressed with other press fittings that have the contour M and are system independent. Our press fittings are produced out of stainless steel 1.4404/316L, in dimensions 15 mm to 108.0 mm. Press fittings delivered will have the standard ethylene propylene diene monomer rubber (EPDM O-ring) gasket already placed in the M profile. Additionally, Swiss Fittings offers the gasket in fluoroelastomer polymer (FPM O-ring) separately. The blue sleeves on the press fittings will detach as soon as the press fittings is pressed.

The demand for stainless steel press fittings and copper press fittings has steadily increased in recent years. Also in North America (USA, Canada), where the product was introduced by Swiss Fittings in 2015, an increase in popularity is noticeable. The DVGW approved fittings complete a secure connection between individual fittings and pipes.

Stainless Steel Ball Valve with Press Ends or Press Fitting Adapter Couplings for Valves

As of 2017 Swiss Fittings has started to offer a 3-Pc. Press ends Ball Valve, M-Contoured press end with ISO-Top for pneumatic actuators. The attached press ends, instead of butt weld ends or threaded ends, allow a direct installation of the valve to the press fittings or pipes. The stainless steel valve controls the flow of liquids and is also delivered with the EPDM O-rings. Larger quantities for valves with press ends can be provided directly from production, also with the pneumatic actuators. If Y-Strainer F/F, Y-Spring Check Valve, Gate Valve, Globe Valve, Swing Check Valve F/F, and 3-way ball valves with either T port or L Port, are needed with press ends, please send us an inquiry for offering directly from production. If these stainless steel valves with press ends are required urgently, we would recommend to use our pressfittings male coupling as an adapter.

Advantages of Stainless Steel and Copper Press Fittings,

Press fittings have an installation advantage with regard to time, safety, and reduction of waste. When using the appropriate press equipment, GDPress fittings can be connected within seconds, reducing the cost of shutdowns and system maintenance. The installation of the press fittings does not require any heavy equipment, flames or cutting of fittings, therefore making it an excellent choice when in a hazardous environment. Except the O-ring, which is preinstalled when shipped by Swiss Fittings, no other sealing, such as Teflon tape or hemp, is necessary.

In private homes and in industry, there are mainly two types of stainless steel and copper press fittings installed, which differ in profile (shape). We generally categorize and differentiate these by M-Contour and V-Contour. The major distributors/brands for copper and stainless steel M-Contour press fittings are VSH Xpress, Mapress (Geberit), and XPress (Seppelfricke), Inoxpres (Raccorderie Metalliche), Eurotubi, and GDPress (Swiss Fittings). Press Fittings with V-Contour are known as Frabopress. Some of these press fittings, including GDPress, are system independent and can be installed with other press fitting brands.

Press fittings have become an important element for fluid transportation and installations. The simple connection, also with stainless steel fittings, valves and flanges make it an ideal tool for 21st-century agriculture, compressed air systems, shipbuilding, and liquid filtrations. Having these components made from stainless steel provides them with even greater, indoor and outdoor application versatility.

There are plenty of adapters and couplings offered in the market that make a transition between flanges, pipes, threaded fittings, and pipe fittings to press fittings possible. The flange coupling M-profile in stainless steel in sizes 15 mm to 108 mm is used to connect a flange based system to a press fittings system. Our stainless steel weld neck flange DIN2633 PN16 DN15 has previously been installed with our press fittings flange coupling 15 mm. The connection of the weld neck flange DIN 2633 then provides the possibility to either connection to a butt weld fitting, such as our welded reducers in 316L, or to a stainless steel welded or seamless pipe. Our elbow 90° female coupling is very often connected with our stainless steel barrel nipples long, to switch from a press fittings system to a threaded and pipe fitting system. By combining threaded fittings and press fittings, the disadvantage of press fittings of not being able to be disconnected after installment, is limited.

Swiss Fittings, Your Press Fittings Supplier

Swiss Fittings has excellent engineers that can support you in developing custom made products with press ends. The direct link to our own production and a wide network of suppliers of raw materials, provides us with the ability to offer, produce, ship, and store the fittings. Past OEM projects have included developing press end components for a filtration and water softener units. Send us your inquiries, and we will have an offer for you within 2-3 days.